Case Study

[Customer Testimonial] AI Becomes the “Nervous System” of Aging Infrastructure: How Company K Transformed Structural Safety Inspections with Vision AI

Hyun Kim

Co-Founder & CEO | 2025/12/30 | 10 min read

![[Infrastructure Safety Inspection] Detect Micro-Defects with AI and Transform Structural Safety Inspections](https://cdn.sanity.io/images/31qskqlc/production/ddc824a6c44de2b9a747802dea6e8cc225c1fdfb-2000x1125.jpg?fit=max&auto=format)

The global infrastructure industry is currently at a critical technological inflection point. This is because the aging of core infrastructure, such as bridges and tunnels, which have underpinned economic growth for decades, has emerged as a global safety issue, accelerating digital transformation (DX) efforts to manage these assets more efficiently.

By 2025, the global Structural Health Monitoring (SHM) market is expected to reach approximately $3.6 billion, with a rapid compound annual growth rate of more than 18.5%. Behind this growth lies a stark reality. According to a 2021 report by the American Society of Civil Engineers (ASCE), U.S. infrastructure received an overall grade of C-, and 42% of bridges were found to be more than 50 years old.

The limitations of a reactive approach that focuses on repair only after problems occur are clear. The market is rapidly shifting toward predictive maintenance (PdM), which uses AI technologies to detect early signs of structural failure and respond in advance.

Company K, which oversees the management of bridges and tunnels, has likewise been confronted with these demands of the time. To address the inefficiencies and safety blind spots of its existing inspection methods, Company K launched a next-generation AI inspection system project in collaboration with Superb AI.

Challenge – Weeks-Long Road Closures and “Invisible” Risks

The biggest challenge Company K faced lay in the fundamental limitations of its traditional visual, manual approach to safety inspections:

- Subjective Judgments and Failed Detection: Traditional inspections required skilled engineers to rely on ropes or special-purpose vehicles to access bridge undersides or tunnel interiors and visually identify defects. With this method, inspection quality varied depending on the engineer’s level of experience and physical condition. In particular, early microcracks or signs of concrete spalling that could ultimately lead to structural collapse were difficult to detect with the naked eye, creating dangerous blind spots in safety inspections.

- Significant Time and Cost Burden: Inspecting a single large bridge in detail could take anywhere from several weeks to several months. This not only resulted in substantial labor costs but also generated considerable social costs due to prolonged road closures.

- Practical Barriers to AI Adoption (The Data Dilemma): Company K considered introducing AI deep learning to resolve these issues, but immediately ran into a “data dilemma.” To train conventional supervised learning AI models, tens of thousands of labeled defect images are typically required. However, defect data representing critical failure signs, such as indicators of imminent collapse, are by definition extremely rare and therefore practically impossible to obtain in sufficient volume.

- Physical Constraints in the Field: To make matters worse, the interiors of bridges and tunnels were often offline environments with poor or no internet connectivity. In addition, for security reasons, it was not permissible to transmit detailed defect images of critical national infrastructure to external cloud servers.

As a result, Company K faced a double burden: it lacked sufficient data to train AI models, and it lacked network connectivity to run AI reliably in the field.

Solution – Zero-Shot AI System That Works Without Labeled Defect Data or Internet Connectivity

To solve the dual challenge of “data scarcity” and “disconnected environment,” Superb AI proposed an innovative AI inspection system built on its Vision Foundation Model (VFM), ZERO.

Core Technology 1: Zero-Shot AI

ZERO breaks with the conventional assumption that AI must be pre-trained on tens of thousands of defect images. With only a small number of “normal” state images, it quickly learns a baseline for what a “normal bridge or tunnel surface” should look like, and immediately flags any signs of deviation as anomalies. This means it can identify (in a “zero-shot” manner) entirely new types of defects it has never been explicitly trained on—such as microcracks, corrosion, or leakage. In other words, it fundamentally resolves the long-standing constraint that “we can’t use AI because we don’t have defect data.”

Core Technology 2: Edge Computing

Superb AI also optimized the AI model to run not on a cloud server, but directly on edge devices mounted on inspection vehicles or portable equipment in the field. As a result, the AI operates in real time even in offline environments where internet connectivity is unavailable. All sensitive infrastructure data is processed entirely on-site without leaving the premises, fully complying with strict data security regulations for critical national infrastructure.

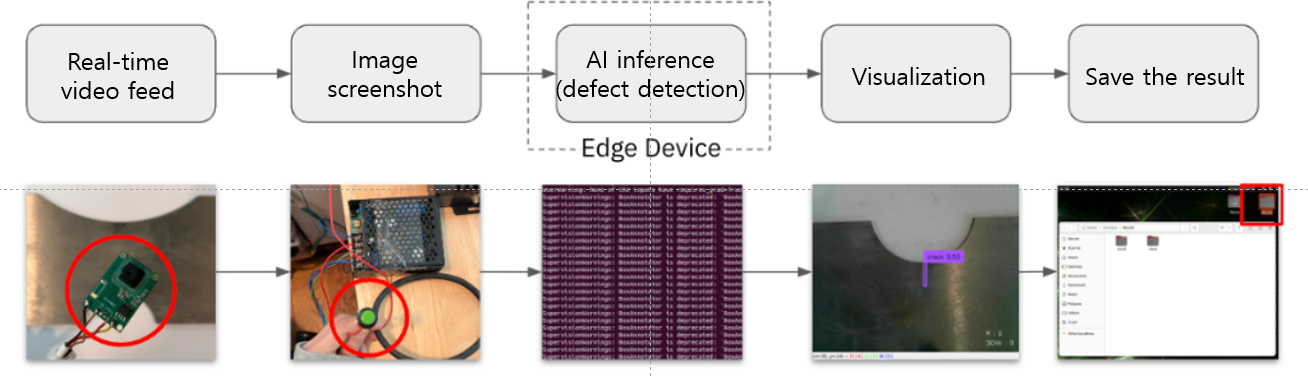

Building an AI-Based Inspection Workflow

Based on the ZERO model, a system that is optimized for Company K’s on-site maintenance and inspection processes was built:

- Real-Time Video Analysis: When inspectors record footage of bridge undersides or tunnel interior walls with a camera, the AI model analyzes the video in real time.

- Immediate Defect Visualization: When the AI detects anomalies such as microcracks, it instantly visualizes the precise location of the defect, its shape (through fine-grained mask segmentation), and the reliability of the detection (“confidence score”) on the operator’s monitor.

- Automatic History Management: All detected defects are automatically stored in a database—along with the corresponding images, classification values such as “presence or absence of cracks,” and detailed inspection parameters (for example, pier location, scan starting point, and more)—enabling systematic, long-term history management.

Benefit – Enabling Predictive Maintenance with Accurate Detection and Faster Response

The introduction of Superb AI’s solution brought immediate, measurable improvements to Company K’s infrastructure maintenance operations:

Quantitative Outcomes:

- Improved Detection Accuracy: Early-stage micro defects that were easily overlooked during visual inspections due to subjective human judgment are now detected according to consistent, objective criteria—blocking risks that could otherwise escalate into catastrophic accidents.

- Reduced Inspection Time and Cost: Through AI-driven real-time automatic analysis, inspection times that previously required several weeks for a single precision survey have been dramatically reduced. This has translated directly into lower labor costs for inspection teams and reduced social costs associated with prolonged road closures.

Qualitative Outcomes:

- Standardized and Objective Inspection Quality: Regardless of individual inspectors’ skill levels or physical condition, AI now performs inspections 24/7 using consistent criteria, raising and standardizing overall inspection quality while making it more objective.

- Data-Driven Decision-Making: All defect data—indexed by location, images, and severity level—is automatically accumulated in Superb Platform. Engineers can now determine maintenance priorities and allocate budgets efficiently based not on “experience,” but on objective, data-driven insights.

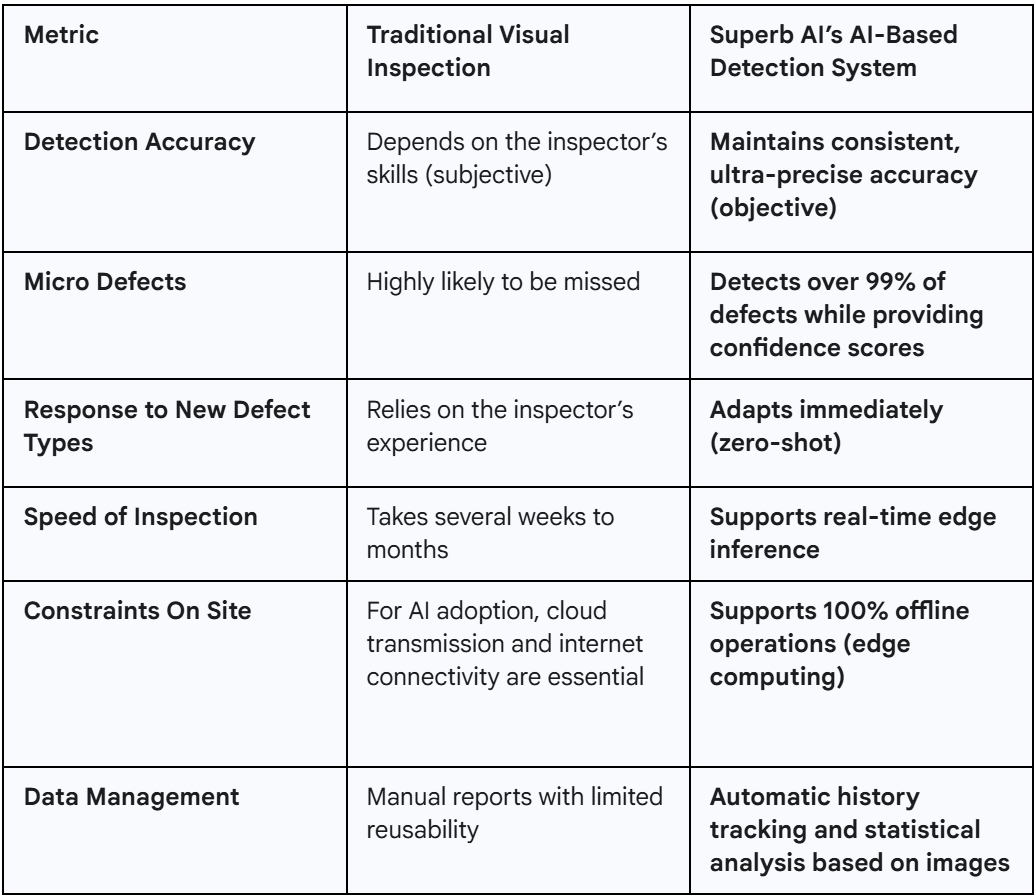

The table below summarizes the key differences between traditional visual inspection and Superb AI’s detection system.

From Detection to Predictive Maintenance

Company K’s innovation did not stop at automating defect detection. Through this project, the company also began systematically accumulating what has become its most valuable asset: data.

By analyzing the accumulated defect data, it is now possible to objectively identify patterns such as which bridge piers develop microcracks, under what climate conditions, what types of cracks occur, and how quickly they progress.

This has laid a powerful foundation for a predictive maintenance system that moves beyond a reactive, “repair after failure” approach. Instead, it enables engineers to forecast the progression of defects and take preemptive action—for example, determining in advance that “this bridge will require repair in six months.”

Just as the predictive maintenance market in the energy sector is projected to reach $2.25 billion by 2025 with an expected compound annual growth rate of 25.77%, data-driven PdM is also becoming a core strategy for enhancing operational efficiency and safety in the infrastructure domain.

Company K’s case provides a clear answer for many infrastructure management organizations that have been hesitant to adopt AI due to constraints such as a lack of defect data and on-site network limitations.

The zero-shot AI + edge computing solution that has been validated on bridges and tunnels can be immediately applied to any critical industrial infrastructure that requires camera-based monitoring but faces similar constraints—data scarcity, offline environments, and strict security requirements—including dams, transmission towers, plant facilities, and aircraft fuselage inspections.

Related Posts

![[Customer Testimonial] “Zero Blind Spots” in Safety Monitoring: How Energy Company E Upgraded Safety Compliance with AI Video Analytics](https://cdn.sanity.io/images/31qskqlc/production/3e01ac9ea55c8e8d73f1bbca5ffbd59357870acc-2000x1125.jpg?fit=max&auto=format)

Case Study

[Customer Testimonial] “Zero Blind Spots” in Safety Monitoring: How Energy Company E Upgraded Safety Compliance with AI Video Analytics

Hyun Kim

Co-Founder & CEO | 7 min read

Case Study

The Future of Airport Security—Synthetic Data for a World Where AI Learns on Its Own

Hyun Kim

Co-Founder & CEO | 5 min read

![[Customer Testimonial] AI-Powered Monitoring Transforms Public Safety and Transportation in G City](https://cdn.sanity.io/images/31qskqlc/production/57b35d88d34cd689145de7b44e0b30ea7ddf8e89-2000x1125.jpg?fit=max&auto=format)

Case Study

[Customer Testimonial] AI-Powered Monitoring Transforms Public Safety and Transportation in G City

Hyun Kim

Co-Founder & CEO | 15 min read

About Superb AI

Superb AI is an enterprise-level training data platform that is reinventing the way ML teams manage and deliver training data within organizations. Launched in 2018, the Superb AI Suite provides a unique blend of automation, collaboration and plug-and-play modularity, helping teams drastically reduce the time it takes to prepare high quality training datasets. If you want to experience the transformation, sign up for free today.