Case Study

[Customer Testimonial] “Zero Blind Spots” in Safety Monitoring: How Energy Company E Upgraded Safety Compliance with AI Video Analytics

Hyun Kim

Co-Founder & CEO | 2026/01/29 | 7 min read

![[Industrial Safety] From Risk Detection to Alerts-Safety Monitoring with Zero Blind Spots](https://cdn.sanity.io/images/31qskqlc/production/3e01ac9ea55c8e8d73f1bbca5ffbd59357870acc-2000x1125.jpg?fit=max&auto=format)

Paradigm Shift in Industrial Safety: From Reaction to Prevention

The global industrial safety landscape is undergoing a fundamental shift. As safety regulations and enforcement continue to strengthen worldwide, companies are being pushed to move beyond reactive responses and adopt prevention-first safety strategies that can be validated in real time.

In South Korea, this shift has been accelerated by expanded regulatory coverage since January 2024, which increased safety and health obligations across a broader range of workplaces. In response, the Korean Ministry of Employment and Labor and the Korea Occupational Safety and Health Agency (KOSHA) have been actively supporting the adoption of AI-based safety equipment among small and mid-sized businesses through programs such as the Smart Safety Equipment Deployment and Expansion Initiative—driving rapid growth in the market. A review of the Ministry’s 2025 workplace supervision plan highlights a notable change in focus: rather than emphasizing paperwork-centered compliance, it places greater weight on “operational effectiveness”—whether hazards are actually being controlled on-site in real time. In other words, it is no longer sufficient to simply install high-cost equipment. What increasingly matters is whether the system detected a real hazard, triggered an alert, and stopped work when needed—and whether those actions are recorded in data logs that can serve as critical evidence for compliance and accountability.

Market Research Future likewise projects that South Korea’s industrial AI market will expand sharply from $3.5 billion in 2024 to $12.5 billion by 2035, noting that rising demand for manufacturing automation—alongside stronger safety enforcement—will be a key driver of this growth. This suggests that AI adoption in industrial safety is not a passing trend, but an essential infrastructure investment tied to business resilience.

Energy Company E is one of South Korea’s leading energy enterprises, playing a central role in the country’s energy sector with a diversified portfolio spanning the LNG value chain, power generation, renewable energy, and city gas supply. Its operating environment differs significantly from a typical manufacturing plant. To eliminate safety blind spots and build a smarter safety management framework, Company E adopted Superb AI Video Analytics.

Challenge – A Complex Energy Environment, From Mobile Operations to Specialized High-Risk Processes

Company E’s worksites are not limited to a single area—they are distributed nationwide. In addition to fixed facilities such as large-scale power plants and storage tank terminals, the company must manage thousands of kilometers of underground pipelines installed beneath urban roads to supply city gas. Pipeline maintenance and new installation work inherently create “mobile worksites,” where locations change daily and even hourly.

Work conditions also vary widely depending on the situation: roads may need to be excavated, cranes installed to lift heavy loads, and confined tanks entered for inspection on an irregular basis. These nonstandard operations involve many unpredictable variables—including weather, ground conditions, and surrounding traffic flow—making rule-based automation insufficient for safety management.In addition, the materials Company E handles include high-pressure gas, flammable fuels, and high-voltage electricity—high-energy sources that can escalate into catastrophic disasters when incidents occur. A single spark during hot work can trigger a major explosion, and oxygen deficiency in confined spaces can take a worker’s life within minutes.

Company E’s key challenges can be summarized as follows:

- Monitoring mobile operations across distributed sites: The company needed safety oversight for mobile cranes and temporary work-at-height areas that fixed CCTV systems cannot cover.

- Managing specialized high-risk processes: It needed real-time verification of hazards such as sparks during hot work and whether workers were wearing required safety equipment during confined-space operations.

- Issuing immediate risk alerts in high-risk environments: The company urgently needed a system capable of detecting early warning signs and issuing alerts instantly—rather than confirming incidents only after they occur.

Solution – A Field-Tailored “Mobile AI Video Analytics System”

To overcome these limitations and achieve its goal of “zero serious incidents,” Company E adopted Superb AI Video Analytics with the objective of building an intelligent data analytics framework—not merely deploying hardware. The core requirements were mobility and high-performance edge AI.

1. Mobile AI CCTV Deployable Anywhere

To cover not only fixed areas but also worksites that change daily, Company E introduced a “mobile AI CCTV” system combining a high-performance edge device (Jetson AGX Orin), a high-resolution camera, and a large-capacity battery. It can operate independently even at outdoor sites without power or communications infrastructure, enabling rapid deployment wherever needed.

2. AI Models Optimized for Real-World Field Conditions

Rather than applying a generic object recognition model, Company E deployed AI models trained on its own on-site data to maximize accuracy.

- Real-time object detection: Workers, safety helmets, forklifts, cranes, and more

- Hazard recognition: Fire smoke/flames, falls, missing safety gear, and more

Key Features – Customized Safety Monitoring Across 4 High-Risk Work Types

Company E selected 4 of the most frequent and high-risk work scenarios and built a focused monitoring system using Superb AI Video Analytics. When a risk event occurs, the system makes an immediate decision on the edge device—without routing through the cloud—and sends an alert within 1 second through on-site speakers or warning lights.

Case 1. Mobile Crane and Work-at-Height Operations

Crane operations and work at height carry high risks of falls and falling-object incidents. Cranes vary widely by type (cargo, hydro, and others), and their shape changes continuously depending on boom angle and extension length—making it difficult for AI to recognize them as a single object. Outriggers are also close to the ground and can be easily obscured by grass or materials.

Superb AI Video Analytics monitors elevated work platforms in real time through multi-object detection and state inference, verifying whether workers have attached their safety lanyards and whether a signaler is positioned within the designated area.

Case 2. Mobile Equipment Operations (Forklifts/Excavators)

Forklifts and excavators are among the top contributors to fatal accidents in industrial settings. Incidents often occur when operator blind spots combine with pedestrian inattention.

Using a distance-estimation algorithm, Superb AI Video Analytics detects forklifts and workers simultaneously. If they come within a predefined distance, the system immediately issues a warning alert to help prevent collisions before they occur.

Case 3. Hot Work (Welding/Cutting)

Hot work in energy plants inherently carries constant risks of explosion and fire. Welding sparks can travel up to 11 meters, enter gaps in sandwich panels or insulation materials, and trigger smoldering. Traditional heat or smoke detectors often activate only after smoke reaches ceiling-mounted sensors, delaying early response. In outdoor worksites, wind can disperse smoke, making detection even more difficult.

Superb AI Video Analytics analyzes flame patterns (color, flicker) and the texture of rising smoke at the pixel level, enabling fire detection within seconds of ignition. It can also distinguish normal sparks generated during welding from abnormal fires that spread to surrounding materials. The system additionally monitors whether the designated fire watch is absent or distracted.

Case 4. Confined-Space Operations

Confined spaces such as underground pipelines and storage tanks carry high risks of asphyxiation due to oxygen deficiency or toxic gas leaks. In many cases, secondary victims occur when rescuers enter without protective equipment—making external awareness and control critical.

During confined-space operations, Superb AI Video Analytics checks whether workers are wearing mandatory safety equipment such as SCBA or supplied-air respirators. It also tracks entry and exit in real time through CCTV installed at the entrance. If the remaining headcount is not zero at the end of work, the system triggers an alarm to indicate that someone may still be inside. (Related case study: https://blog-ko.superb-ai.com/ai-video-monitoring-ppe-compliance-case-study/)

Benefit – Establishing a Data-Driven Safety Management Framework

Quantitative Outcomes: Reducing Incident Costs and Improving Efficiency

- Reduced labor costs and smarter workforce allocation: One mobile AI CCTV unit can monitor continuously, 24/7, without fatigue. With 360-degree rotation and a wide-angle lens, it can effectively cover work that would otherwise require 2-3 human monitors. This enables Company E to redeploy personnel from routine monitoring into more specialized safety roles or technical work.

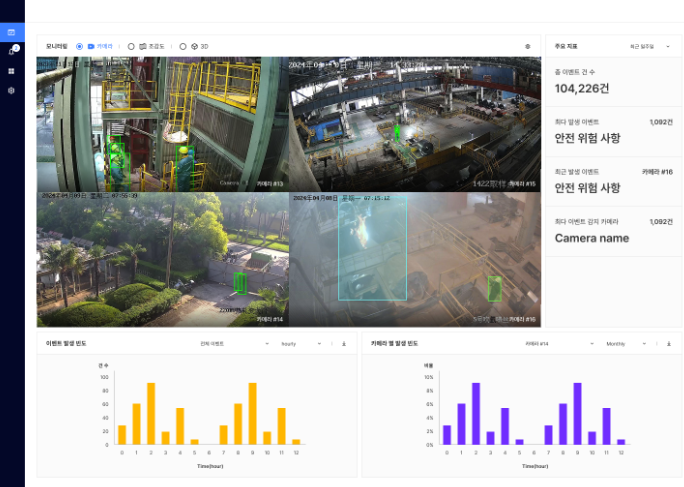

Sample dashboard of Superb Video Analytics

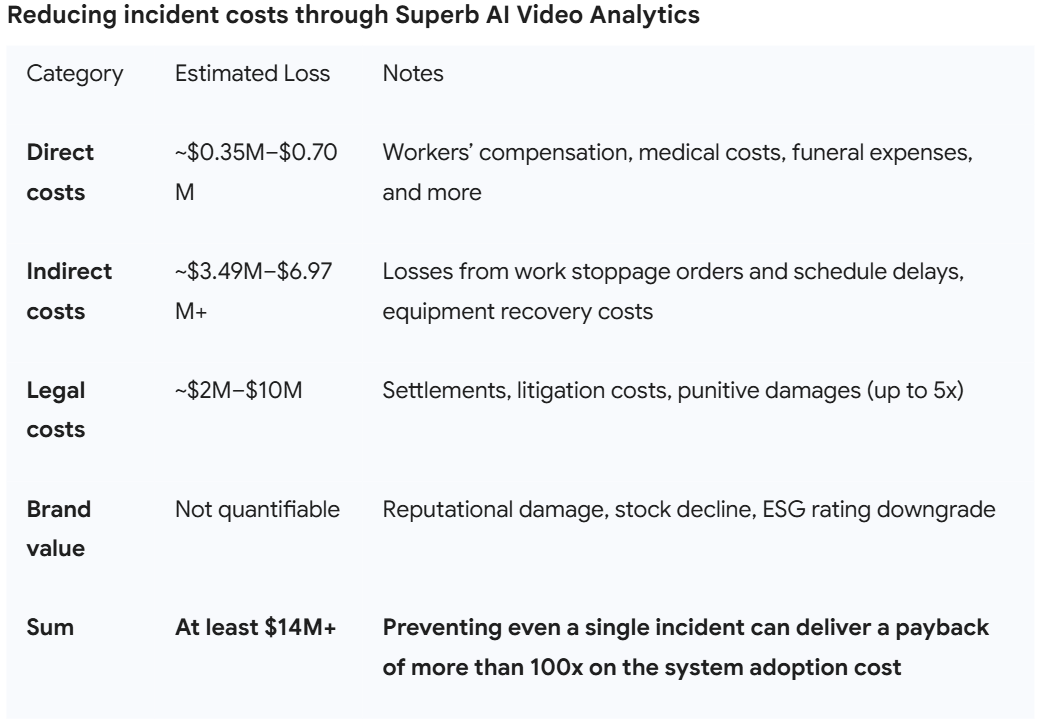

- Avoided incident-related costs: Under stronger safety enforcement, the cost of a serious incident can include legal expenses, substantial fines, revenue losses due to work stoppages, and long-term reputational damage—potentially reaching extremely large totals. Preventing even a single minor incident can deliver immediate return on investment (ROI).

Reducing incident costs through Superb AI Video Analytics

Qualitative Outcomes: Embedding a Data-Driven Safety Culture

- Objective evidence for decision-making: Instead of vague directives like “Wear your helmet,” teams can make concrete, data-led decisions such as, “There were 15 helmet noncompliance cases in Zone A last week, so targeted training is required.”

- A psychological safety mechanism: Intelligent CCTV deployed on-site reinforces workers’ sense that they are continuously protected—and simultaneously monitored—discouraging unsafe behavior.

- A stronger compliance and defense posture: Even if an unavoidable incident occurs, the system can serve as objective digital evidence that the company adopted state-of-the-art safety technology and fulfilled its duty of care.

Superb AI Video Analytics is not simply about installing high-performance CCTV. It represents the deployment of a comprehensive “digital safety platform” built on (1) real-time responsiveness through edge computing, (2) higher accuracy through field-specific data training, and (3) continuous AI performance advancement through cloud-based improvements. Especially when combined with smart infrastructure and ground monitoring systems that energy companies like Company E are already building—such as drone-based capabilities—it can form a seamless, three-dimensional safety net.

As safety regulations and expectations continue to strengthen worldwide, adopting AI-based safety systems is no longer optional—it is a business resilience strategy. Superb AI is helping establish a new standard for digital transformation for safety across industrial sites.

Related Posts

Case Study

The Future of Airport Security—Synthetic Data for a World Where AI Learns on Its Own

Hyun Kim

Co-Founder & CEO | 5 min read

![[Customer Testimonial] AI Becomes the “Nervous System” of Aging Infrastructure: How Company K Transformed Structural Safety Inspections with Vision AI](https://cdn.sanity.io/images/31qskqlc/production/ddc824a6c44de2b9a747802dea6e8cc225c1fdfb-2000x1125.jpg?fit=max&auto=format)

Case Study

[Customer Testimonial] AI Becomes the “Nervous System” of Aging Infrastructure: How Company K Transformed Structural Safety Inspections with Vision AI

Hyun Kim

Co-Founder & CEO | 10 min read

![[Customer Testimonial] AI-Powered Monitoring Transforms Public Safety and Transportation in G City](https://cdn.sanity.io/images/31qskqlc/production/57b35d88d34cd689145de7b44e0b30ea7ddf8e89-2000x1125.jpg?fit=max&auto=format)

Case Study

[Customer Testimonial] AI-Powered Monitoring Transforms Public Safety and Transportation in G City

Hyun Kim

Co-Founder & CEO | 15 min read

About Superb AI

Superb AI is an enterprise-level training data platform that is reinventing the way ML teams manage and deliver training data within organizations. Launched in 2018, the Superb AI Suite provides a unique blend of automation, collaboration and plug-and-play modularity, helping teams drastically reduce the time it takes to prepare high quality training datasets. If you want to experience the transformation, sign up for free today.