Insight

Choosing The Right Computer Vision Camera

Hyun Kim

Co-Founder & CEO | 2025/03/07 | 10 min read

Choosing the Right Camera for Your Industrial and Manufacturing Vision AI Applications

Computer vision applications rely on high-quality image data, and selecting the right camera is critical to ensuring optimal performance. Whether you're conducting industrial inspections, threat detection, or automating defect detection, different camera types offer unique advantages.

In this guide, we’ll explore the four main types of cameras used in industrial and manufacturing vision AI applications, their use cases, and key integration considerations.

1. Area Scan Cameras: Ideal for Still Image Inspections

example of Area Scan cameras

Overview

Area scan cameras capture full 2D images in the visible (RGB) spectrum, making them a great choice for scenarios where objects pause or stop for inspection. These cameras are common in manufacturing quality control, where products move through discrete steps and can be imaged in a stationary position.

Use Cases

- Quality assurance on assembly lines (e.g., checking defects in electronics or mechanical parts)

- General industrial inspections where a clear, still image is sufficient

Key Considerations

- Works best in controlled lighting conditions

- Requires the production line to pause briefly for snapshots

- Easy to integrate into existing machine vision systems

- PoE cameras are generally recommended over USB for more stable image ingestion

Examples of Area Scan Cameras

- Lucid Vision Labs: Develops high-precision area scan cameras engineered for industrial automation, delivering sharp, full-frame imaging for quality control and manufacturing inspection.

- IDS: Offers USB and GigE area scan cameras designed for seamless integration into industrial production lines, ensuring reliable defect detection and process monitoring.

- MindVision Technology: Provides industrial-grade area scan cameras optimized for high-speed inspection, electronics manufacturing, and precision imaging in automated quality assurance systems.

2. SWIR (Short-Wave Infrared) Cameras: Seeing Beyond the Visible Spectrum

example of a SWIR camera

Overview

SWIR cameras operate in wavelengths beyond human vision, allowing them to detect defects invisible to standard RGB cameras. These cameras are especially useful for material inspection, moisture detection, and identifying hidden anomalies.

Use Cases

- Food inspection (e.g., detecting moisture content, spotting foreign objects)

- Material quality analysis, such as detecting defects in plastics, textiles, or semiconductors

Key Considerations

- Higher cost than standard RGB cameras

- Can analyze chemical composition (e.g., water absorption properties)

- Often requires specialized lighting and filters for accurate results

Examples of SWIR cameras

- Lucid Vision Labs: Offers SWIR cameras featuring Sony's SenSWIR sensors, providing high-resolution imaging across a broad spectrum.

- 1stvision : 1stvision provides SWIR cameras available with GigE interfaces and line scan imaging suitable for continuous motion application

3. Line Scan Cameras: Continuous Monitoring for High-Speed Production Lines

example of Line Scan cameras

Overview

Line scan cameras capture images one line at a time, stitching them together into a full 2D image. These cameras are perfect for high-speed production lines where objects move continuously and cannot pause for inspection.

Use Cases

- Inspection of continuous materials, such as paper, steel sheets, textiles, or plastic films

- Fast-moving conveyor belt applications, where products need to be inspected without stopping

Key Considerations

- Requires precise synchronization between camera, conveyor speed, and sensors

- Demands dedicated lighting for consistent image capture

- Frame grabbers (e.g., Matrox Zebra) help encode continuous image data

Essential Components & Vendors

- Cameras: Crevis, Mindvision

- Proximity Sensor: Keyence (to trigger scanning at the right moment)

- Interface: CameraLink for high-speed data transfer

- Frame Grabber: Matrox (Zebra) for data processing

Examples of Line Scan cameras

- Crevis: Offers line scan cameras with high sensitivity and speed, supporting standard CameraLink interfaces.

- MindVision Technology: Provides 10GigE industrial line scan cameras suitable for high-speed data transmission.

4. CCTV Cameras: Industrial Monitoring & Security

example of CCTV cameras

Overview

CCTV cameras are not designed for detailed defect inspection, but they are excellent for facility monitoring, security, and operational oversight. These cameras offer continuous video streaming and are often used to monitor manufacturing plants and warehouses.

Use Cases

- Factory and facility safety monitoring

- Perimeter security and surveillance

- Tracking general operational processes

Key Considerations

- Optimized for monitoring, not detailed analysis

- Works best when real-time video streaming is needed

- RTSP protocol recommended for reliable network streaming

- Utilizing cameras with PTZ (pan, tilt, zoom) capabilities for range of motion larger visual coverage

Protocols & Compatibility

- RTSP for network streaming

- MQTT for IoT integration

- USB camera input for direct system connections

Examples of CCTV cameras

- Axis Communications: Offers a wide range of network cameras suitable for various surveillance needs.

- Hikvision: Provides network cameras designed for diverse applications, from video security to business intelligence.

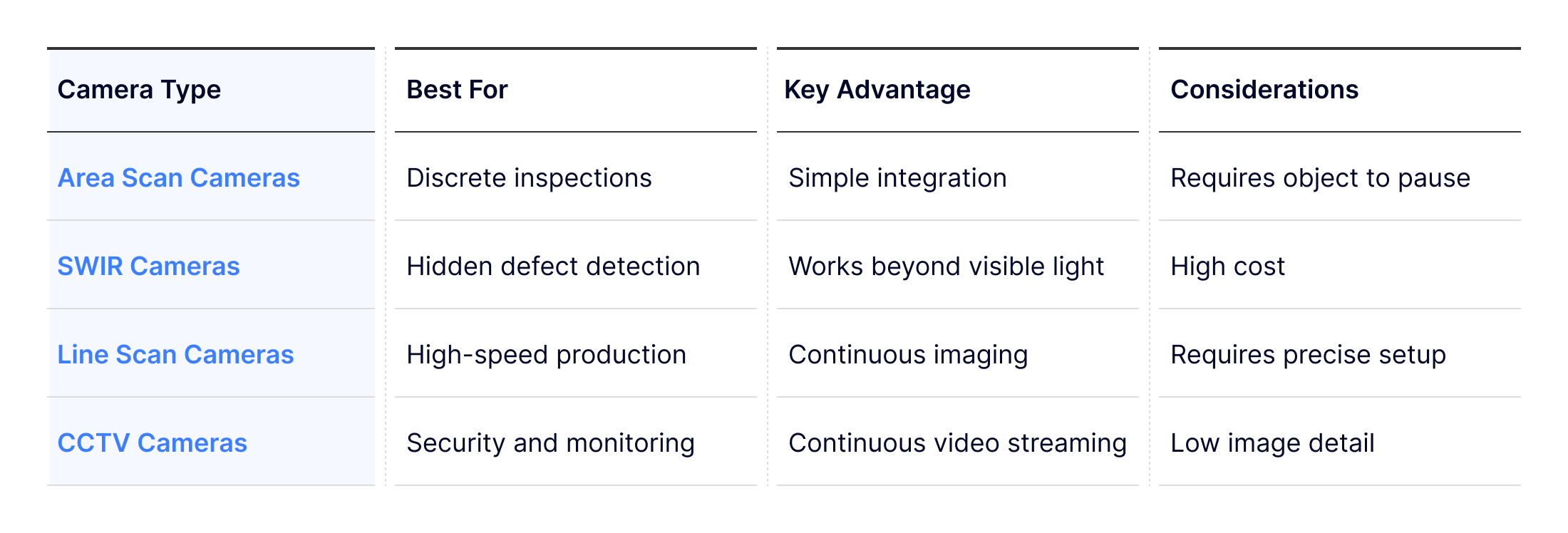

Bringing It All Together: Choosing the Right Camera for Your Needs

The best camera for your computer vision project depends on your specific use case:

Need Help with Hardware Setup & Integration?

Selecting the right camera is just the first step—proper installation and system integration are crucial to ensuring optimal performance. That’s where Superb AI’s Model Services can help.

What Superb AI’s Model Services Can Do for You:

- On-Site Factory Visits – Assess your production line and recommend the best hardware setup

- Hardware Consulting – Determine which camera type suits your workflow, AI hardware requirements and use case needs

- Edge Device Installation – Set up on-premise AI processing to streamline real-time decision-making

- Model Building and Deployment – Everything from data processing, augmentation and labeling to model building and deployment

Looking for an expert partner to help integrate AI-powered computer vision into your factory? Get in touch with us today!

Final Thoughts

Choosing the right camera for your computer vision system depends on your application, environment, and required accuracy. Whether you need high-speed production line monitoring, hidden defect detection, or large-scale security coverage, selecting the right hardware and integrating it properly will maximize efficiency and performance.

By leveraging the right cameras, AI-powered vision models, and system integrators, you can unlock new levels of automation, quality control, and efficiency in your operations.

Related Posts

Insight

⑤ From Seeing to Governing Actions: The Technological Revolution from Vision AI to Physical AI

Hyun Kim

Co-Founder & CEO | 7 min read

![[Physical AI Series 4] A Strategy for Successful Physical AI Adoption: A 4-Step Execution Roadmap to Maximize ROI](https://cdn.sanity.io/images/31qskqlc/production/0768d35871b72179ee4901195cd5d4bb1a582340-2000x1125.png?fit=max&auto=format)

Insight

[Physical AI Series 4] A Strategy for Successful Physical AI Adoption: A 4-Step Execution Roadmap to Maximize ROI

Hyun Kim

Co-Founder & CEO | 18 min read

![[Physical AI Series 3] The Brain of Physical AI: Robot Foundation Models and Data Strategy](https://cdn.sanity.io/images/31qskqlc/production/d7e66e5540113ef407d54fe6013920ef0cbffd6e-2000x1125.png?fit=max&auto=format)

Insight

[Physical AI Series 3] The Brain of Physical AI: Robot Foundation Models and Data Strategy

Hyun Kim

Co-Founder & CEO | 7 min read

About Superb AI

Superb AI is an enterprise-level training data platform that is reinventing the way ML teams manage and deliver training data within organizations. Launched in 2018, the Superb AI Suite provides a unique blend of automation, collaboration and plug-and-play modularity, helping teams drastically reduce the time it takes to prepare high quality training datasets. If you want to experience the transformation, sign up for free today.