Case Study

[Customer Testimonial] Preventing Safety Incidents with AI Video Surveillance: Ensuring Compliance with Evolving Safety Regulations

Hyun Kim

Co-Founder & CEO | 2025/11/18 | 5 min read

![[Construction & Shipyard Safety Monitoring] Detect potential hazards in real time with AI-powered safety analytics](https://cdn.sanity.io/images/31qskqlc/production/b3b896923ec33b5f6055b66df58fb458cfb31bb6-2000x1125.jpg?fit=max&auto=format)

In busy construction and shipbuilding sites where multiple machines and workers move constantly, forklift-related injuries can occur at any moment. In fact, last year, a worker was fatally struck by a forklift at a manufacturing plant in Korea, resulting in a significant fine for the employer under Korea’s newly reinforced workplace safety laws. As global safety regulations become more stringent, on-site managers now face growing legal and financial responsibility for safety violations. However, traditional manual monitoring alone makes it difficult to detect potential hazards in advance.

The recent surge in forklift accidents often stems not from mechanical failures but from human factors—such as inattention, unsafe driving habits, and inadequate management systems. According to a study on serious industrial incidents and fatalities conducted by the Korean government, common causes of forklift incidents include uneven terrain, collisions with nearby structures, and poor visibility. Reports from the U.S. Occupational Safety and Health Administration (OSHA) show that pedestrians account for 36% of all forklift fatalities.

In other words, monitoring high-risk proximity zones around forklifts can significantly reduce accidents. This testimonial highlights how a global shipbuilder partnered with Superb AI to deploy an AI-powered video monitoring system that detects hazards in real time and prevents near-miss incidents.

Challenge – Persistent On-Site Hazards

The client, a leading shipbuilder, operates large-scale yards where heavy equipment and workers move simultaneously without pause. Despite implementing a comprehensive safety management system, two critical risks remained unresolved:

- ① Unpredictable Risk of Forklift Collision: In narrow spaces where worker paths overlap with forklift routes, the risk of collisions was constant. Even trained monitoring staff found it nearly impossible to identify the subtle precursors to collisions or crush injuries in real time.

- ② Challenges with Managing Work-at-Height Safety: Supervisors could not visually confirm, for every worker on scaffolds dozens of meters above ground, whether safety harnesses and lifelines were properly attached. It was physically impossible to check all workers continuously through visual inspection alone.

Solution – Real-Time Event Detection with AI

Superb AI collaborated closely with the client to co-develop the most effective solution using actual on-site data.

Phase 1: Preparing Real-World Data for AI Training

- Collected CCTV footage directly from the client’s worksites and processed it end-to-end within Superb Platform—from data ingestion, auto-parsing, filtering, and AI-assisted labeling to model training, evaluation, and deployment. This allowed rapid development of custom AI models with minimal data and ongoing performance improvement.

- Supplemented missing environmental variations (e.g., weather, lighting changes) through the synthetic data generation feature on Superb Platform to enhance the model’s real-world adaptability. This laid the foundation for the AI models to recognize real-world situations and make informed judgments accurately.

Phase 2: Developing an AI Model to Tackle the Challenges

To address the two main problems identified in the field, Superb AI rapidly developed custom AI models that suit customer needs:

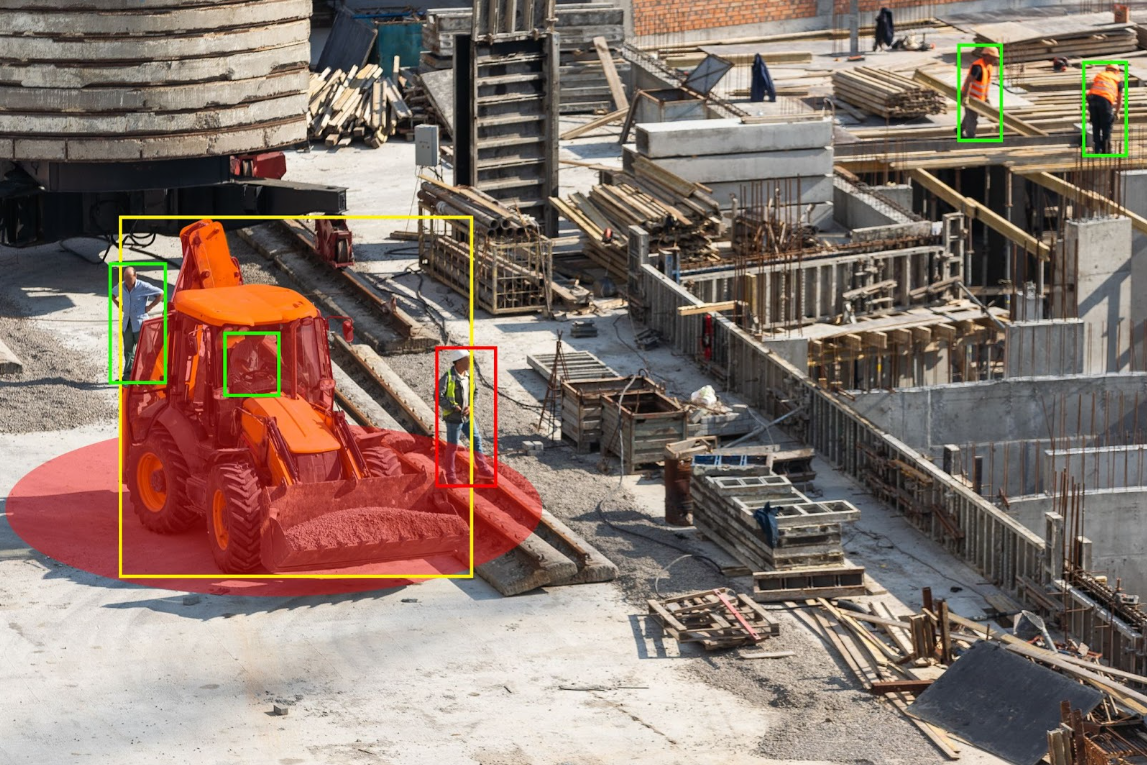

- Solution 1) Forklift Safety Detection AI for Incident Prediction and Prevention

Beyond detecting forklifts and people, the AI analyzed trajectory and speed to define invisible, real-time “risk zones.” When a worker entered these zones, the system detected the potential collision risk and issued immediate alerts. - Solution 2) Safety Harness Detection AI for Safety Compliance

The AI recognized safety belts, lifelines, and carabiners worn by workers at height, determining whether they were properly fastened. If a harness was not secured, the worker was highlighted in red on the screen, and the supervisor instantly received the individual’s location and details.

(Sample image of AI detecting a worker approaching the forklift “risk zone”)

Benefit – Proactive Accident Prevention and Compliance with Safety Regulations

Following the adoption of AI video monitoring, the client achieved the following measurable outcomes:

- Significant Reduction in Accidents and Near Misses

- Superb AI’s Video Analytics solution identifies objects and behaviors in real time to detect hazards before incidents occur. Supervisors can immediately identify workers entering high-risk zones and take swift preventive action.

- Enhanced Compliance and Audit-Ready Documentation

- All detected events—such as entry into restricted zones or missing PPE—are automatically recorded, providing legal evidence of safety compliance for employers. With built-in Vision-Language Models (VLMs), the system supports natural-language searches of past incidents and automatically generates detailed reports.

- Improved Operational Efficiency and Cost Savings

- Companies that have adopted AI-based monitoring report tangible ROI, including a 15% reduction in insurance premiums and an 83% drop in safety violations. The shipyard also significantly reduced downtime and compensation costs associated with forklift and work-at-height incidents.

- Data-Driven Training and Continuous Improvement

- By analyzing event data and video records, supervisors can identify recurring risk patterns and provide targeted safety training for specific workers—helping strengthen workplace safety culture and prevent recurrence.

Scalability – Expanding to Diverse Safety Scenarios

The accumulated data and AI capabilities developed through this project can be extended in multiple directions:

- Support for More Heavy Equipment

- Detect near misses around other heavy equipment, such as cranes, excavators, and hull assembly areas, by defining dynamic risk zones.

- Enterprise-Wide Safety Management Platform

- Leverage VLM-based video search and natural-language reporting to manage all safety data in one platform and automatically generate compliance reports aligned with safety standards.

- Broader Industry Applications

- Add modules for tasks such as detecting workers without wearing insulated gloves or specialized PPE, issuing restricted-area entry alerts, and recognizing falls or slips—adapting the system to different industrial environments.

Conclusion – Setting a New Standard for On-Site Safety

Forklift collisions and falls from height remain among the most serious safety risks in construction and shipbuilding. Manual monitoring alone can no longer ensure prevention. Superb AI’s video analytics solution has set a new safety standard by defining risk zones in real time and accurately detecting and tracking objects to prevent accidents. By using an end-to-end AI platform that handles everything—from data preparation and model development to deployment and performance monitoring—the company shortened development cycles and continuously improved detection accuracy.

According to McKinsey, AI-based predictive tools can reduce workplace incidents by up to 30%. Sites that have implemented AI safety systems report a 47% reduction in PPE violations, a 36% drop in reportable incidents, and a 52% improvement in hazard identification. Superb AI’s solution can scale across equipment types and operations—empowering organizations worldwide to elevate workplace safety and ensure compliance with evolving safety regulations.

Related Posts

![[Case Study] Superb AI and CS WIND Achieve AI-Powered Innovation in Wind Tower Manufacturing Accelerated by NVIDIA Technologies](https://cdn.sanity.io/images/31qskqlc/production/ccb477f7cb943b79ce53e65d55ea58692e587da7-2809x1585.png?fit=max&auto=format)

Case Study

[Case Study] Superb AI and CS WIND Achieve AI-Powered Innovation in Wind Tower Manufacturing Accelerated by NVIDIA Technologies

Hyun Kim

Co-Founder & CEO | 10 min read

![[Customer Testimonial] Enhancing Business Sustainability with AI Cargo Fleet Monitoring](https://cdn.sanity.io/images/31qskqlc/production/8bb2e73e53528309cece74ad4b99453c223b1568-2000x1125.jpg?fit=max&auto=format)

Case Study

[Customer Testimonial] Enhancing Business Sustainability with AI Cargo Fleet Monitoring

Hyun Kim

Co-Founder & CEO | 5 min read

![[Customer Testimonial] Achieving 98% PPE Compliance with AI Video Surveillance](https://cdn.sanity.io/images/31qskqlc/production/b92f1fc37f27f8da8e2731cd21e3be49da0f9a87-2000x1125.jpg?fit=max&auto=format)

Case Study

[Customer Testimonial] Achieving 98% PPE Compliance with AI Video Surveillance

Hyun Kim

Co-Founder & CEO | 5 min read

About Superb AI

Superb AI is an enterprise-level training data platform that is reinventing the way ML teams manage and deliver training data within organizations. Launched in 2018, the Superb AI Suite provides a unique blend of automation, collaboration and plug-and-play modularity, helping teams drastically reduce the time it takes to prepare high quality training datasets. If you want to experience the transformation, sign up for free today.