Case Study

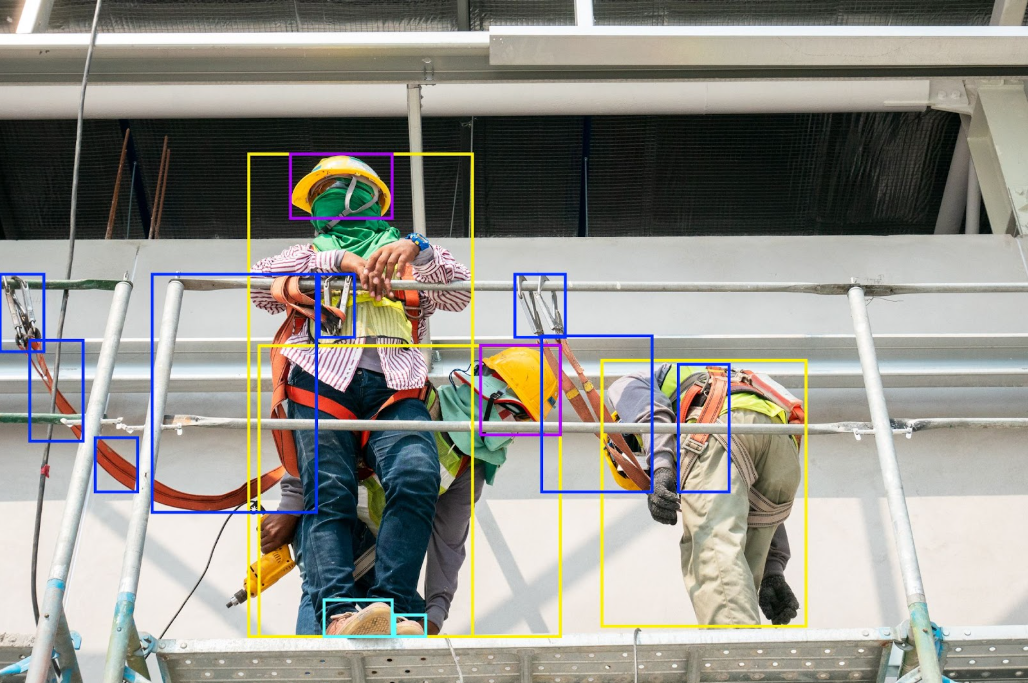

[Customer Testimonial] Achieving 98% PPE Compliance with AI Video Surveillance

Hyun Kim

Co-Founder & CEO | 2025/11/28 | 5 min read

![[PPE Compliance Detection] Automatically detect PPE compliance to prevent major accidents](https://cdn.sanity.io/images/31qskqlc/production/b92f1fc37f27f8da8e2731cd21e3be49da0f9a87-2000x1125.jpg?fit=max&auto=format)

In industrial workplaces worldwide, safety monitoring remains a significant challenge. According to the latest industrial accident statistics from Korea’s Ministry of Employment and Labor, manufacturing—along with construction—is one of the highest-risk sectors for fatal accidents. Every year, hundreds of workers are killed or injured at work, and many accidents are caused by human factors, such as the failure to wear personal protective equipment (PPE).

The introduction of stricter safety regulations across many countries has fundamentally changed how organizations approach workplace safety. These laws not only impose financial penalties for accidents but also hold business owners and executives directly accountable for failing to ensure worker safety and compliance. Around the world, manufacturing companies have faced severe legal and financial consequences due to accidents involving entrapment, collisions, or explosions.

Today, businesses are not only expected to prevent accidents but also to provide objective data proving that robust safety management systems are in place. In this environment—where safety failures can immediately translate into managerial failures—traditional, reactive monitoring systems are no longer sufficient to ensure corporate sustainability.

Challenge – Outdated Safety Solutions Struggling to Keep Up with Changes

A leading manufacturing company in Korea attempted to address the risks of the Serious Accident Punishment Act, one of Korea’s strictest safety regulations, by increasing its safety staff and expanding its CCTV systems. However, maintaining 100% PPE compliance remained a challenge.

The company turned to AI video surveillance but quickly ran into technical barriers. The key issue was the rigidity of their existing AI model.

Core Challenge: AI-Powered Safety Management, Trapped in Endless “Retraining” Cycles

- The Burden of Continuous Retraining: Traditional, custom-trained CCTV models perform well when recognizing specific PPE items such as helmets or safety boots. However, industrial environments are dynamic and ever-evolving. New protective gear—safer helmets, specialized gloves, or enhanced face shields—is frequently introduced to improve safety and efficiency. With traditional AI systems, each update required a lengthy and costly retraining process involving data collection, labeling, model retraining, and system redeployment—a cycle that could take months and consume significant resources.

- Safety Gaps from Lack of Flexibility: When new PPE was introduced, automatic monitoring was suspended until retraining was completed, creating “safety gaps.” During this period, supervisors had to rely on manual visual inspections, undermining the very purpose of AI—continuous, uninterrupted safety monitoring.

- Low ROI Due to Constant Maintenance Costs: Frequent changes in equipment and environments led to repeated retraining and maintenance costs, reducing the overall return on investment (ROI) for AI deployment. The company needed a sustainable solution that could flexibly adapt to evolving safety standards instead of relying on static, pre-trained models.

Ultimately, what the company required was not a fixed AI system that had to be retrained repeatedly, but an intelligent and adaptive one that could evolve with changing workplace conditions—an AI capable of keeping pace with the real world beyond simply replacing human eyes.

Solution – Achieving Flexibility with “Learning-Free AI”

Faced with the limitations of conventional AI systems, the company adopted Superb AI’s Video Analytics solution, which offered a fundamentally different approach. The company chose Superb AI not merely for its AI technology, but for its innovative solution to one of the biggest challenges in AI implementation—flexibility.

Core Technology: Combining Zero-Shot Learning and Semantic Search

Superb AI’s system uses a “Detect & Search” approach that combines two advanced technologies instead of relying on traditional “custom training.”

- Phase 1: Rapid Detection with Zero-Shot Vision Models

Superb AI’s powerful zero-shot vision foundation model detects people and various PPE objects (e.g., helmets, safety glasses, gloves) directly from live video feeds without the need for additional training data. Despite the lack of custom training, it achieves high accuracy across general object categories. - Phase 2: Precise Identification with Semantic Search

To determine whether the detected PPE is approved or compliant, the system applies the semantic search technology. Safety managers pre-register images of approved helmets, boots, and other PPE into a vector database (DB). The AI then compares the visual features of detected PPE against the registered images, instantly verifying whether it is authorized or not.

Immediate Adaptability to Change

This method delivers exceptional flexibility and scalability. For example, when a new helmet design is introduced, safety managers simply upload an image of it to the database—no retraining required. The AI immediately begins recognizing it as approved PPE.

This “learning-free” approach delivered significant value for the company:

- Instant On-Site Adaptation: New PPE is integrated into the monitoring system immediately upon introduction, eliminating “safety gaps.”

- Cost and Time Savings: By removing the need for repeated data collection, labeling, and retraining, the company reduced the total cost of ownership (TCO) and accelerated operational efficiency.

- Future-Proof Safety Management: The system can flexibly accommodate any new PPE in the future, building a sustainable, forward-looking safety platform.

Superb AI’s Video Analytics solution, integrated into the company’s existing CCTV infrastructure, automatically highlighted workers violating PPE rules and sent real-time alerts to supervisors’ dashboards and mobile devices. As a result, the company achieved a major transformation—from reactive detection to real-time prevention, and from rigid systems to adaptive intelligence.

Benefit – A Paradigm Shift in Safety and Efficiency

Superb AI’s Video Analytics solution delivered a positive, organization-wide impact on safety culture and operational efficiency.

Quantitative Outcomes: Change Proven by Data

After deployment, the results were clear and measurable:

- Dramatic Improvement in PPE Compliance

Under the previous manual oversight with blind spots, PPE compliance was estimated at ~75%. After implementing the AI system, compliance stabilized at 98%+ across all monitored zones. - 90% Reduction in Safety Violations

Always-on, real-time monitoring heightened safety awareness across the workforce. Within just three months, daily PPE violations fell by 90%+, establishing compliance as the new on-site norm. - Faster Hazard Detection and Response

Instead of taking hours—or going unnoticed—violations now trigger alerts within 30 seconds, enabling rapid intervention and response.

Key KPI Comparison (Before vs. After Superb AI)

Qualitative Outcomes: A Fundamental Shift in Safety Culture

Beyond changes in numbers, the company has experienced a remarkable change in its safety culture:

- Data-Driven Decision-Making

The system automatically produces statistics on when, where, and what types of PPE violations occur. Safety teams used these insights to install PPE stations in specific areas, adjust work procedures, and address root causes—moving from ad-hoc fixes to continuous improvement. - Stronger Regulatory Readiness

Every violation and corrective action is timestamped and archived, creating audit-ready evidence that safety obligations are being met. During investigations or audits under evolving safety regulations, the company could demonstrate systematic, ongoing compliance with objective data.

Beyond PPE: The Path to an Integrated Safety Platform

What the company gained most was scalability. This isn’t just a “PPE detector,” but a flexible AI safety platform that adapts to diverse scenarios without lengthy retraining.

Built on zero-shot vision and semantic search, managers can add new safety functions without complex development, including:

- Forklift–Worker Collision Prevention: Define dynamic “risk zones” around moving forklifts; send instant alerts when workers approach.

- Restricted-Area Intrusion Detection: Flag unauthorized entries into zones with high voltage or hazardous chemicals to prevent major incidents.

- Fall/Slip Detection: Detect falls for workers at height or on slippery floors to trigger a rapid response.

- Fire/Smoke Detection: Complement sensors with video analytics to catch early visual signs and protect the golden time.

Superb AI’s solution evolves from point tools into a centralized AI Safety Command Center that unifies all visual safety risks—more efficient and cost-effective than assembling fragmented point solutions from multiple vendors.

Field Safety Is Business Safety

This success story delivers a clear message: decades-old, reactive supervision is no longer sufficient for today’s complex, fast-changing industrial environments. By embracing “learning-free AI,” the company moved beyond the limits of rigid systems—achieving safety, efficiency, and regulatory assurance together.

In an era of tightening safety regulations, proactive, data-driven safety management is not optional—it’s essential for business continuity. Superb AI’s Video Analytics solution lowers the barriers to advanced AI adoption, enabling organizations to build world-class safety systems with practical cost and lead time.

If you’d like to move beyond traditional CCTV to a proactive, data-driven safety management approach, leave your details below—Superb AI experts will reach out shortly.

Related Posts

![[Customer Testimonial] AI-Powered Monitoring Transforms Public Safety and Transportation in G City](https://cdn.sanity.io/images/31qskqlc/production/04a439013022ef3deef3e1886b6e9d728362518c-1025x687.png?fit=max&auto=format)

Case Study

[Customer Testimonial] AI-Powered Monitoring Transforms Public Safety and Transportation in G City

Hyun Kim

Co-Founder & CEO | 15 min read

![[Case Study] Superb AI and CS WIND Achieve AI-Powered Innovation in Wind Tower Manufacturing Accelerated by NVIDIA Technologies](https://cdn.sanity.io/images/31qskqlc/production/ccb477f7cb943b79ce53e65d55ea58692e587da7-2809x1585.png?fit=max&auto=format)

Case Study

[Case Study] Superb AI and CS WIND Achieve AI-Powered Innovation in Wind Tower Manufacturing Accelerated by NVIDIA Technologies

Hyun Kim

Co-Founder & CEO | 10 min read

![[Customer Testimonial] Enhancing Business Sustainability with AI Cargo Fleet Monitoring](https://cdn.sanity.io/images/31qskqlc/production/8bb2e73e53528309cece74ad4b99453c223b1568-2000x1125.jpg?fit=max&auto=format)

Case Study

[Customer Testimonial] Enhancing Business Sustainability with AI Cargo Fleet Monitoring

Hyun Kim

Co-Founder & CEO | 5 min read

About Superb AI

Superb AI is an enterprise-level training data platform that is reinventing the way ML teams manage and deliver training data within organizations. Launched in 2018, the Superb AI Suite provides a unique blend of automation, collaboration and plug-and-play modularity, helping teams drastically reduce the time it takes to prepare high quality training datasets. If you want to experience the transformation, sign up for free today.