Case Study

[Case Study] Superb AI and CS WIND Achieve AI-Powered Innovation in Wind Tower Manufacturing Accelerated by NVIDIA Technologies

Hyun Kim

Co-Founder & CEO | 2025/12/04 | 10 min read

![[Case Study] Innovate Wind Tower Manufacturing with AI by Achieving 99.99% Accuracy in Material Identification](https://cdn.sanity.io/images/31qskqlc/production/ccb477f7cb943b79ce53e65d55ea58692e587da7-2809x1585.png?fit=max&auto=format)

CS WIND, the world’s largest wind tower manufacturer, has adopted Superb AI’s Vision AI technology together with NVIDIA AI infrastructure to automate and optimize its production processes.

CS WIND operates multiple production sites worldwide, manufacturing massive wind towers that can reach 660 ft (200 meters) in height and weigh up to 1.4M lbs (700 tons). However, the enormous physical scale, complex logistics flows, and manual data logging practices made it difficult to maximize operational efficiency.

This case study takes a closer look at how CS WIND overcame these physical constraints, addressed two core challenges—“automated manufacturing process monitoring” and “steel plate material tracking”—and how Superb AI’s Vision AI technology and NVIDIA AI infrastructure formed the foundation of this transformation.

Challenge 1 – Manual Process Monitoring and Data Blind Spots

Wind tower manufacturing is a long-cycle project that can take up to ten weeks and involves multiple stages, such as cutting, welding, and assembly, with hundreds of underlying substeps. Under the previous system, CS WIND faced the following limitations:

- Limitations of manual data entry: Operators had to manually record the start and end of each process step on paper or enter them directly into the MES (Manufacturing Execution System). This led to frequent data omissions and input errors, making it difficult to identify bottlenecks or inefficient procedures in real time.

- Lack of process visibility: In work areas obscured by massive structures, it was difficult to see which tasks were in progress. As a result, “operational blind spots” emerged where, even when bottlenecks occurred, the root cause could not be immediately identified.

Solution 1 – Real-Time Process Analytics with NVIDIA Blueprint for video search and summarization (VSS) and Superb AI’s VFM and VLM

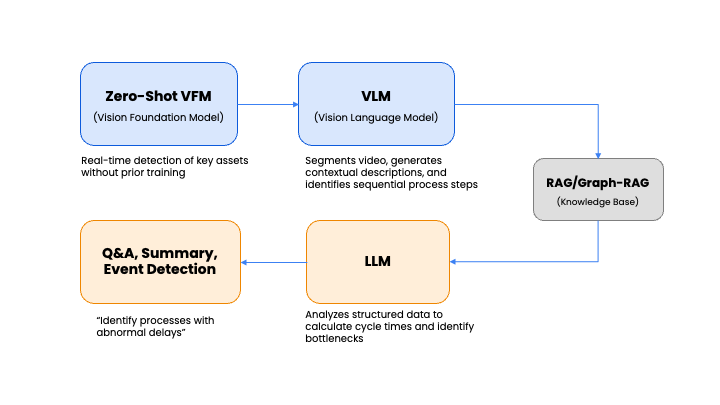

To address these issues, Superb AI proposed a hybrid solution that combines its proprietary Vision Foundation Model (VFM), ZERO, with a Vision Language Model (VLM).

1. Instant Object Detection Without Additional Training (Zero-Shot VFM)

Traditional AI development required several months to collect field data, label it, and train AI models. In contrast, Superb AI’s proprietary VFM “ZERO” can recognize key assets—such as workers, cranes, and welding machines—without any additional training (“zero-shot”), dramatically shortening the time-to-deployment.

2. AI That Understands Time and Context (Temporal & Context Awareness)

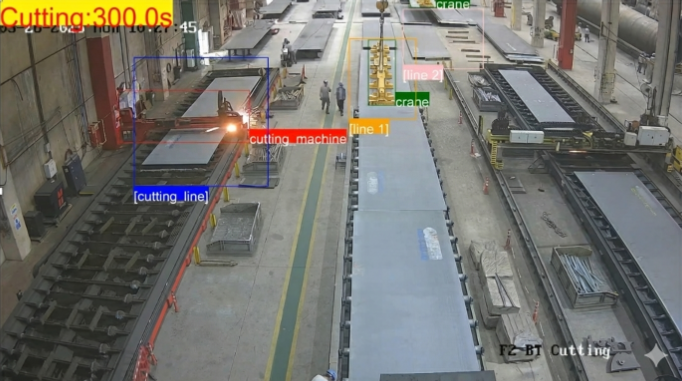

Beyond simply detecting objects, the solution applies VLM technology to analyze the temporal flow and context of live video feeds. The VLM understands whether the current step is in a “preparation” phase or an “active welding” phase in chronological order. It can interpret and describe situations such as “the crane is moving a steel plate” or “welding has been in progress for 10 minutes” in text. This enables automatic calculation of cycle time for each process step and real-time detection of delays.

(Architecture combining Superb AI’s ZERO with a VLM)

(Architecture of NVIDIA VSS Blueprint)

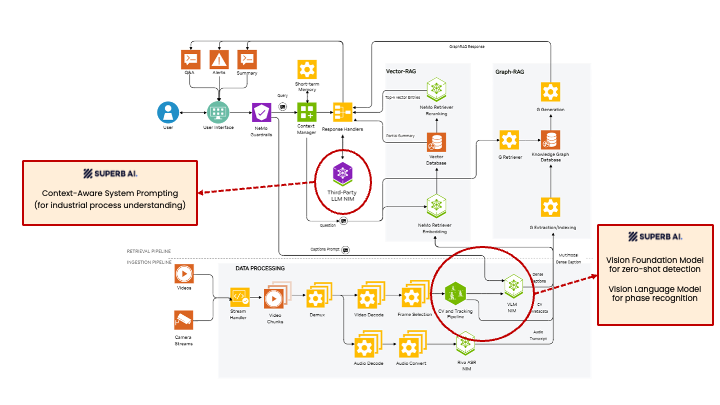

3. Intelligent Video Management Accelerated by NVIDIA VSS Blueprint

To support the large-scale video analytics pipeline, the NVIDIA VSS Blueprint was introduced. NVIDIA VSS Blueprint is a part of the NVIDIA Metropolis platform and combines generative AI, VLMs, LLMs, RAG, and media management services to develop visually perceptive and interactive visual AI agents.

VSS indexes the metadata generated by Superb AI, allowing managers to instantly search and analyze specific footage using natural language queries such as “bottleneck in the cutting process yesterday afternoon.”

(Example of video being analyzed in real time and logged every second by Superb AI’s model)

Challenge 2 – Illegible Handwritten IDs and Material Loss

The second major challenge lay in managing the raw material—steel plates. Inside the plant, where thousands of plates move each day, each plate was identified solely by a handwritten identification code applied by workers.

- Illegible handwriting and numerous variables: Each worker’s handwriting style differed, and plates were often hanging from cranes or positioned at various angles, making it practically impossible for conventional OCR (Optical Character Recognition) technology to read the codes reliably.

- Material tracking failures: Manual input errors frequently caused mismatches between the inventory location recorded in the system and the actual physical location of materials, often leading to lost plates. This resulted in significant time wasted searching for materials and, in some cases, misrouted plates that halted production lines.

(Example of handwritten steel plate identification codes that are difficult to read. The IDs shown in the above are sample IDs for illustration purposes only and do not represent actual IDs)

Solution 2 – Generative OCR and NVIDIA Jetson Edge Computing

To overcome the limitations of conventional OCR, Superb AI developed and deployed its own Generative AI–based OCR (“Generative OCR”) pipeline, delivering a step-change improvement in handwritten character recognition accuracy. Also, to run these advanced AI models on-site without latency, the company leveraged the NVIDIA Jetson Orin platform for real-time data processing.

1. Superb AI’s Three-Stage High-Precision Recognition Pipeline

Superb AI designed a proprietary three-stage algorithm to achieve extremely high recognition accuracy.

- Step 1. Smart ROI Cropping & Alignment: First, the Vision AI model locates the steel plate and automatically rectifies the orientation of any characters, correcting text that may be rotated at any angle or flipped.

- Step 2. VLM-Based Generative OCR: The aligned image is then processed by a Generative OCR model, which infers and converts even highly stylized or partially obscured handwriting into text. Rather than simple pattern matching, the AI interprets the contextual structure of the characters.

- Step 3. Temporal Aggregation: Instead of relying on a single reading, the system cross-validates recognition results across dozens of sequential frames of the same plate and confirms the final ID with the highest confidence.

(Example of Superb AI’s high-precision recognition pipeline. The IDs shown above are sample IDs for illustration purposes only and do not represent actual IDs)

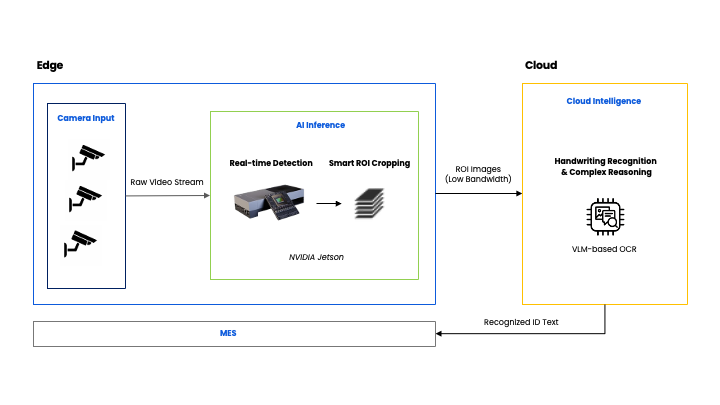

2. Hybrid Edge Architecture Powered by NVIDIA Jetson

Running all of these complex computations solely in the cloud would introduce network latency and additional communication costs. To avoid this, Superb AI deployed NVIDIA Jetson Orin modules at the edge, directly connected to the cameras.

- NVIDIA Jetson (Edge AI Inference): Network conditions inside the plant can be unstable, and from a security perspective, sending all video data to the cloud is often inefficient. By leveraging NVIDIA Jetson Orin modules, Superb AI processed data immediately at the edge, where the cameras are installed, instead of transmitting everything to a central data center.

- High-performance edge computing: Thanks to the powerful GPU performance of NVIDIA Jetson to seamlessly run large transformer models, computationally intensive tasks—such as detecting plate regions in high-resolution images, rectifying rotated text, and recognizing complex handwritten characters—could all be executed in real time.

(Hybrid edge architecture built on NVIDIA Jetson Orin)

Instead of sending entire video streams, Superb AI transmitted only the regions that require AI judgment—such as Regions of Interest (ROIs) or text regions—from edge devices to AWS Cloud, where they are integrated with the MES (Manufacturing Execution System). This efficient hybrid edge–cloud architecture saved bandwidth while maintaining real-time performance.

Result – Achieving Data-Driven Visibility Across the Manufacturing Process

The combination of Superb AI’s Vision AI technology and NVIDIA AI infrastructure has fundamentally transformed CS WIND’s production environment.

- Improved process efficiency and increased throughput: Accurate cycle time analysis enabled CS WIND to identify and eliminate bottlenecks, improving end-to-end process efficiency. Even a 5% reduction in time per sub-process can significantly shorten total lead time, ultimately increasing annual production capacity.

- 99.9% material identification accuracy: With Generative OCR, even highly stylized or hard-to-read handwritten codes can be digitized with near-perfect accuracy, reducing material tracking failures to virtually zero.

- End-to-end digital traceability: Every step—from material inbound to final tower shipment—is now recorded automatically, enabling transparent production management with no data blind spots.

Building a Fully Digital Manufacturing Environment with AI

CS WIND’s industrial AI transformation project is a prime example of how cutting-edge AI technologies can be applied to solve long-standing challenges in manufacturing.

Superb AI provided a high-performance platform and AI models tailored to industrial environments, while NVIDIA supported the optimal AI infrastructure, including Jetson and VSS. Because the solution combines cloud-based management with edge-based on-site processing in a hybrid architecture, it can be rapidly deployed across CS WIND’s global facilities in Vietnam, the United States, Portugal, and beyond. Process optimization also leads directly to reduced energy consumption, supporting CS WIND’s RE100 commitments and carbon reduction goals. The company is now moving toward an end-to-end digital manufacturing footprint with no data blind spots.

In CS WIND’s manufacturing environment, the joint solution from Superb AI and NVIDIA has made what was previously “unseen” visible (visibility), what was “unmeasurable” measurable (measurability), and ultimately what was “uncontrollable” controllable (controllability). Superb AI will continue to advance its AI technologies to support the sustainable growth of the wind energy industry.

Related Posts

![[Customer Testimonial] “Zero Blind Spots” in Safety Monitoring: How Energy Company E Upgraded Safety Compliance with AI Video Analytics](https://cdn.sanity.io/images/31qskqlc/production/3e01ac9ea55c8e8d73f1bbca5ffbd59357870acc-2000x1125.jpg?fit=max&auto=format)

Case Study

[Customer Testimonial] “Zero Blind Spots” in Safety Monitoring: How Energy Company E Upgraded Safety Compliance with AI Video Analytics

Hyun Kim

Co-Founder & CEO | 7 min read

Case Study

The Future of Airport Security—Synthetic Data for a World Where AI Learns on Its Own

Hyun Kim

Co-Founder & CEO | 5 min read

![[Customer Testimonial] AI Becomes the “Nervous System” of Aging Infrastructure: How Company K Transformed Structural Safety Inspections with Vision AI](https://cdn.sanity.io/images/31qskqlc/production/ddc824a6c44de2b9a747802dea6e8cc225c1fdfb-2000x1125.jpg?fit=max&auto=format)

Case Study

[Customer Testimonial] AI Becomes the “Nervous System” of Aging Infrastructure: How Company K Transformed Structural Safety Inspections with Vision AI

Hyun Kim

Co-Founder & CEO | 10 min read

About Superb AI

Superb AI is an enterprise-level training data platform that is reinventing the way ML teams manage and deliver training data within organizations. Launched in 2018, the Superb AI Suite provides a unique blend of automation, collaboration and plug-and-play modularity, helping teams drastically reduce the time it takes to prepare high quality training datasets. If you want to experience the transformation, sign up for free today.