Insight

CVPR 2025 Object Instance Detection Challenge: Advancing Practical AI for Industrial Applications

Hyun Kim

Co-Founder & CEO | 2025/06/24 | 15 min read

CVPR 2025 Object Instance Detection Challenge: Advancing Practical AI for Industrial Applications

CVPR (Conference on Computer Vision and Pattern Recognition), one of the most prestigious conferences in the computer vision field, is once again drawing global attention in 2025. Among its many programs, the "Object Instance Detection Challenge" hosted as part of the "Visual Perception and Learning in an Open World" workshop stands out as a highlight.

This challenge goes beyond academic interest, as it focuses on core technologies that are becoming increasingly relevant in our daily lives—particularly in robotics. It serves as a testbed for practical AI technologies that can be directly applied in real-world industrial settings. Specifically, it assesses the key capabilities necessary for the rapid and effective deployment of robotics and AI across various industries, including manufacturing, logistics, healthcare, and security.

Why Is “Object Instance Detection” Essential for Industrial AI?

Limitations of Traditional Object Detection in Industrial Applications

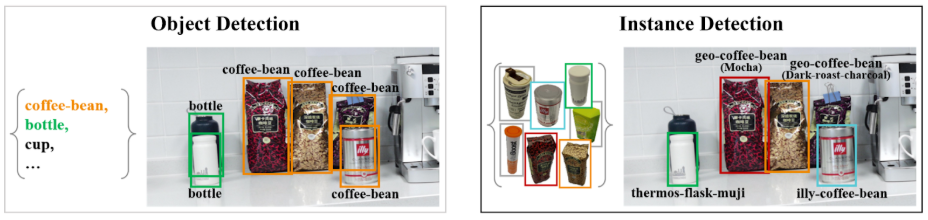

The core difference between traditional object detection and object instance detection lies in generalization versus specialization. While conventional object detection aims to identify “any cup,” which focuses on the AI’s ability to generalize, instance detection aims to find “that specific cup.”

Traditional object detection focuses on locating objects that belong to predefined categories, such as "chair," "cup," or "book." However, this approach has clear limitations when applied to real-world industrial environments.

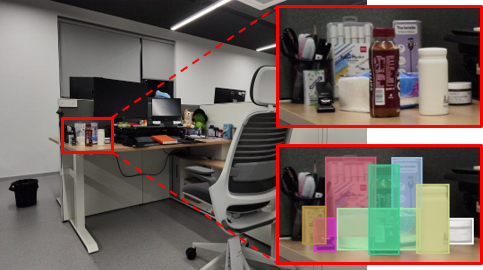

(Difference between Traditional Object Detection vs. Object Instance Detection)

In manufacturing, detecting “a bolt” and identifying an exact "M8 × 20mm stainless hex bolt" are two entirely different tasks. Similarly, in a logistics center, locating “a box” is very different from locating “a specific delivery box with Amazon order number #123456789.”

Industrial Value of Instance Detection

Object Instance Detection (InsDet) aims to detect specific object instances defined by a few reference images. This is exactly what is needed in industrial environments. These environments are full of unpredictable conditions, unfamiliar settings, and unexpected object arrangements. InsDet is a core capability that allows robots to operate effectively and contribute meaningfully in such open-world scenarios.

1. Innovation in Manufacturing

- Quality Control: Automatically detect and filter out products with defects identical to known faulty samples

- Assembly Lines: Assemble the exact part in the correct position (from dozens of similar-looking components)

- Inventory Management: Identify specific parts among thousands stored in a warehouse

2. Innovation in Logistics

- Automated Sorting: Locate a specific customer’s item among tens of thousands of packages

- Inventory Auditing: Accurately verify stock for specific brands and models among hundreds of shelf items

- Picking Robots: Mobilize robots in Amazon’s Kiva-style warehouses to pick only the correct items with precision

3. Innovation in Healthcare

- Medical Device Management: Locate medical devices specifically required for each patient among numerous pieces of hospital equipment

- Drug Management: Distinguish the correct prescription from lookalike medication bottles

- Surgical Tools: Identify the exact tool among a complex set of instruments in an operating room

CVPR 2025 Object Instance Detection Challenge: A Real-World Benchmark for Industrial Applications

Simulating Real Industrial Environments

This year’s CVPR 2025 Object Instance Detection Challenge features a larger and more challenging dataset than previous InsDet studies. Its greatest strength lies in how realistically it simulates what indoor robots actually encounter. It recreates scenarios where robots must identify specific objects in cluttered and chaotic indoor spaces from a distance—conditions more reflective of real homes, offices, and warehouses than tidy lab environments. In short, the dataset reflects the complexity and uncertainty of real-world industrial environments.

1. High-Resolution Product Catalog Simulation

- 100 distinct object instances: Each captured at ultra-high resolution of 3072×3072 pixels

Images taken at 15-degree intervals: Provided full 360-degree product views, similar to an actual product catalog

360-degree image capture at 15-degree intervals

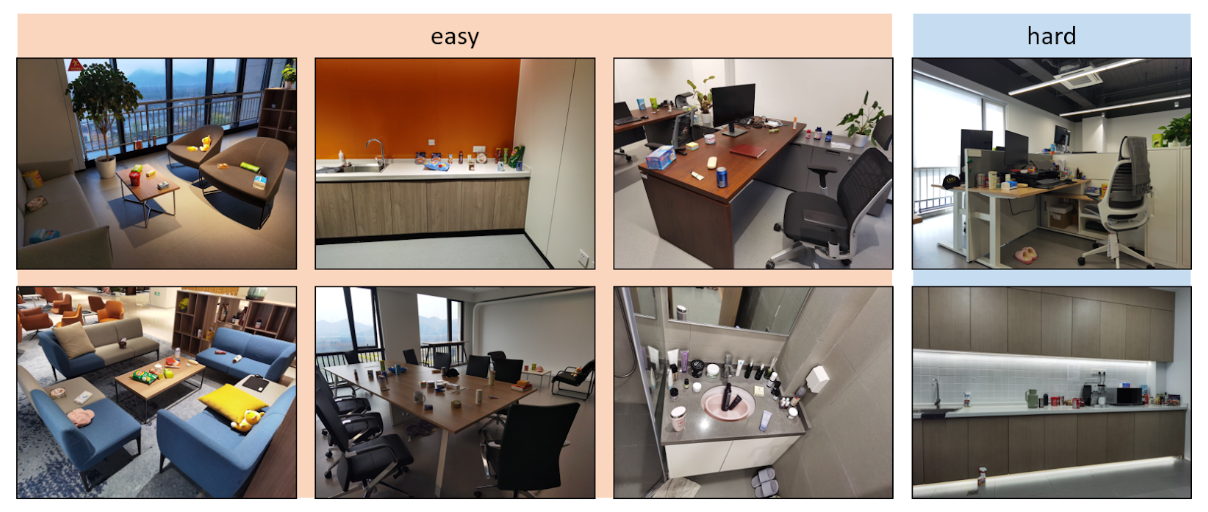

2. Realistic Work Environment Simulation

- 160 real-scene images: Complex scenes captured at 6144×8192 resolution

- Cluttered workspaces: Realistic complexity found in manufacturing sites, warehouses, and stores

- Categorized by difficulty: Reflects various levels of complexity seen in real industrial environments

Scenes organized by difficulty level

Strict Evaluation Protocol

The challenge evaluates performance based on bounding box predictions. The evaluation metrics are as follows:

- AP (Average Precision): Overall detection accuracy

- Difficulty-based evaluation: Analysis of performance across easy and hard scenes

- Size-based evaluation: Analysis of performance across small, medium, and large object sizes

- AR (Average Recall): Ability to find all relevant objects without missing any

This multifaceted evaluation allows for clear identification of each model’s strengths and weaknesses.

Strict Conditions for Industrial Practicality

Key constraint: Participants are not allowed to train their models on the actual test scene images. This mirrors real-world scenarios, where robots must correctly recognize trained objects in environments they have never encountered before.

This constraint is a critical factor in evaluating a model’s generalization capability. It measures how well a model trained only on multi-angle profile images and background data can perform in completely new test scenes.

Why is this condition important for industry?

- Adaptability to new work environments: No need to retrain every time robots are deployed in new factories or warehouses

- Immediate deployment: Ready for use in the field with just product catalog images

- Cost-efficiency: No need for separate data collection and training per site

Key Technical Challenges of the Instance Detection Challenge

Pushing the Limits of Few-Shot Learning

Models must learn to detect objects perfectly using only a small number of reference images (24 multi-angle shots). This demands a highly efficient learning ability similar to how humans learn.

Viewpoint Invariance

Models must be able to recognize the same object even when viewed from unexpected angles or under unfamiliar lighting conditions, based on the handful of provided multi-angle profile images.

Robustness in Complex Environments

Accurate detection must be possible even in cluttered and complex real-world environments. The model must overcome challenges such as lighting changes and background complexity.

Instance detection is a fundamental technology that enables robots to evolve from simple task performers into truly intelligent partners.

We look forward to seeing what innovative approaches global researchers will present at CVPR 2025 and how these will shape the future of robotics. The fact that domain-specialized vision foundation models are being validated in such a prestigious international competition marks a significant opportunity to secure global leadership in next-generation industrial AI technology. Stay tuned for updates on Superb AI’s performance in the Object Instance Detection Challenge.

Related Posts

Insight

⑤ From Seeing to Governing Actions: The Technological Revolution from Vision AI to Physical AI

Hyun Kim

Co-Founder & CEO | 7 min read

![[Physical AI Series 4] A Strategy for Successful Physical AI Adoption: A 4-Step Execution Roadmap to Maximize ROI](https://cdn.sanity.io/images/31qskqlc/production/0768d35871b72179ee4901195cd5d4bb1a582340-2000x1125.png?fit=max&auto=format)

Insight

[Physical AI Series 4] A Strategy for Successful Physical AI Adoption: A 4-Step Execution Roadmap to Maximize ROI

Hyun Kim

Co-Founder & CEO | 18 min read

![[Physical AI Series 3] The Brain of Physical AI: Robot Foundation Models and Data Strategy](https://cdn.sanity.io/images/31qskqlc/production/d7e66e5540113ef407d54fe6013920ef0cbffd6e-2000x1125.png?fit=max&auto=format)

Insight

[Physical AI Series 3] The Brain of Physical AI: Robot Foundation Models and Data Strategy

Hyun Kim

Co-Founder & CEO | 7 min read

About Superb AI

Superb AI is an enterprise-level training data platform that is reinventing the way ML teams manage and deliver training data within organizations. Launched in 2018, the Superb AI Suite provides a unique blend of automation, collaboration and plug-and-play modularity, helping teams drastically reduce the time it takes to prepare high quality training datasets. If you want to experience the transformation, sign up for free today.