Insight

Top 3 Safety Issues in Manufacturing: What Kind of Video Monitoring Is Needed to Address Them?

Tyler McKean

Head of Customer Success | 2025/07/11 | 15 min read

Top 3 Safety Issues in Manufacturing: What Kind of Video Monitoring Is Needed to Address Them?

With safety regulations being reinforced year after year, ensuring safety in manufacturing environments has become a legal requirement rather than a choice. According to statistics released by the Korean Ministry of Employment and Labor, a total of 589 workers died from industrial accidents in Korea in 2023, with 175 of those fatalities occurring in the manufacturing sector—an increase of five cases (2.9%) compared to the previous year. The rise was especially notable in specific sectors such as shipbuilding and repair, underscoring the urgent need to strengthen safety and health capabilities among small businesses and high-risk industries. As a result, many manufacturing sites are seeking solutions that go beyond human monitoring, which is often limited by attention fatigue and delayed emergency response—factors that can lead to even greater damage.

Against this backdrop, Superb AI’s Video Analytics solution is gaining attention as a powerful tool for addressing safety challenges in manufacturing and mitigating the legal risks associated with workplace safety laws.

In this post, we’ll take a look at the 3 most common safety challenges in manufacturing and how Superb AI’s Video Analytics helps solve them.

Top 3 Safety Challenges in Manufacturing and How to Solve Them

1. Challenge: Limited Real-Time Hazard Detection and Labor-Intensive MonitoringSolution: Zero-Shot AI Model that Doesn’t Require Pre-Training, Combined with Automatic Anomaly Alerts

Challenges on the Ground:

- Traditional AI can only detect predefined hazards (e.g., fire, falls) and cannot recognize new or unexpected risk types

- Detecting new hazards or adapting to process changes requires 3–6 months of AI model development and retraining

- Model development demands skilled personnel and large volumes of training data

- Existing AI models are vulnerable to environmental changes, such as lighting conditions or camera angles, leading to reduced accuracy

Superb AI’s Video Analytics Solution:

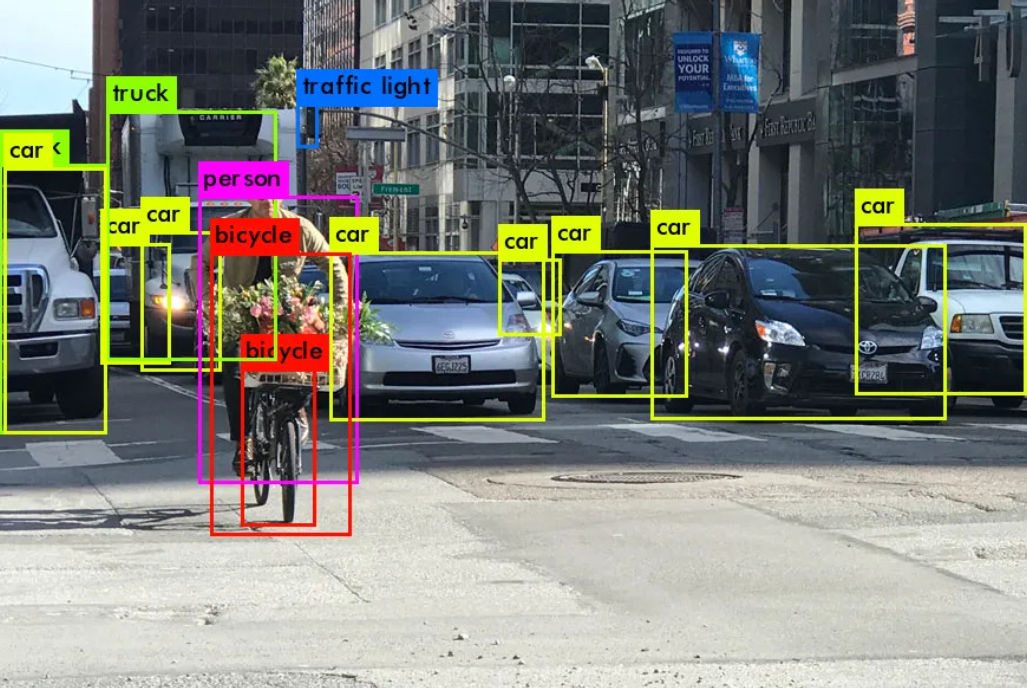

- Detects objects and hazards in real time using an AI model that requires no pre-training (“zero-shot technology”)

- Identifies dynamic, evolving risks—not just fixed categories like “fire,” “falling,” or “no helmet”

- Integrates seamlessly with existing CCTV systems

- Triggers automatic alerts to enable immediate response when anomalies are detected

A metal manufacturing company operating on a three-shift production schedule faced significant challenges in safety management. During night shifts in particular, limited supervisory staff could only perform periodic patrols, resulting in blind spots. After implementing Superb AI’s Video Analytics, the company was able to utilize its existing CCTV infrastructure while enabling 24/7 real-time monitoring.

The most significant improvement was the flexibility in hazard detection. Unlike the previous system, which could only detect predefined scenarios, Superb’s solution could instantly identify a wide range of risks tailored to on-site conditions—such as “not wearing a mask during welding,” “forklift speeding,” or “working at height without a safety harness.” Even as the work environment changed, the system could adapt in real time simply by entering new keywords, significantly enhancing the agility of safety management.

2. Challenge: Inefficiency in Incident Search and Analysis Due to Manual Data HandlingSolution: Natural Language Video Search (Video Retrieval)

Challenges on the Ground:

- Incident investigations require significant time and manpower

- Difficult to locate specific scenes within massive volumes of CCTV footage

- Challenging to gather the evidence needed for compliance with safety regulations

- Lack of structured data for analyzing and preventing recurring incidents

Superb AI’s Video Analytics Solution:

- Enables intuitive video search using natural language queries

- Supports convenient natural language-based searches like “the section of Line 3 where the toxic gas leak occurred yesterday”

- Automatically converts video content into text through video captioning technology

- Automatically categorizes and stores footage by incident type for structured data management

A chemical manufacturing company previously spent an average of 3 days analyzing the causes of safety incidents involving hazardous substances. After adopting Superb AI’s Video Analytics solution, the company was able to immediately search for footage using queries like “scene of hazardous material leakage in a specific area.” As a result, investigation times were reduced to under 3 hours. This allowed them to quickly analyze patterns in similar incidents and implement preventive measures—providing key documentation to fulfill regulatory obligations for preventing incident recurrence.

3. Challenge: Need to Redesign Monitoring Systems Whenever the Layout or Production Line ChangesSolution: Automated 3D Spatial Map Generation Technology

Challenges on the Ground:

- Need to rebuild safety management systems every time a production line is reconfigured

- Limited intuitiveness and flexibility of traditional 2D floor plan-based monitoring

- Difficulty in identifying and controlling hazardous zones accurately

- Limited ability to analyze the relationship between worker movement and potential risks

Superb AI’s Video Analytics Solution:

- Automatically generates 3D spatial maps using just a smartphone camera

- Auto-calculates camera positions and angles for seamless system mapping

- Tracks worker locations in real time and issues warnings when they enter danger zones

- Uses spatial intelligence to analyze dwell times and congestion by zone

A large logistics company operating a massive distribution center—spanning 50,000 square meters and handling same-day delivery of products ranging from fresh food to home appliances and beauty items—employs over 500 workers simultaneously. First-time temporary workers often got lost in the facility.

The biggest challenge was responding quickly to safety incidents. With hundreds of CCTV cameras installed throughout the warehouse, locating individual workers in real time was nearly impossible, resulting in delayed emergency responses. In some cases, site managers were unable to pinpoint the exact location of incidents during emergencies, which delayed the arrival of rescue teams.

After implementing Superb AI’s 3D spatial auto-mapping feature, managers could generate an accurate digital map of the facility simply by recording the interior with a smartphone. By mapping existing CCTV footage to the model, real-time worker tracking became possible. If a hazard, such as a fall or collision, was detected, the system would immediately send an alert to the nearest manager with precise location information.

As a result, emergency response times were reduced to under 2 minutes on average. The system also used spatial intelligence to analyze and optimize worker movement paths. Furthermore, when new workers approached restricted or hazardous zones, automatic warnings were triggered to prevent potential accidents in advance.

Key Technological Differentiators: How Superb AI Stands Apart from Conventional Video Analytics Solutions

1. AI that Detects Anything (Detection AI): Immediate Risk Detection and Rapid Response

Traditional AI monitoring systems typically require at least 3 to 6 months of model development to detect newly emerging risk factors. Superb AI overcomes this limitation with its vision foundation model, which is capable of detecting virtually anything without the need for retraining.

This enables organizations to swiftly meet safety law requirements to adjust safety management systems in response to changes in the working environment. Furthermore, because the solution is integrated with our MLOps platform, even highly specific and complex scenarios—such as abnormal machine behavior—can be addressed by developing customized models up to 90% faster than with conventional methods.

2. Efficient Video Retrieval & Captioning: Automated Legal Evidence Collection

One of the most critical challenges in complying with safety regulations is being able to prove that safety management obligations have been fulfilled. Superb AI automates this process through natural language-based video search and automatic video captioning technologies.

For example, when labor inspectors requested that Company X provide a report on “all safety violations and corresponding actions taken over the past three months,” a team of three safety managers previously had to manually review CCTV footage over the course of a week. After adopting Superb’s solution, they were able to retrieve all related incidents and corrective actions within just 10 minutes by simply searching, “show me all cases of workers not wearing safety helmets in the past 3 months.”

Superb AI’s Visual Language Model (VLM) technology automatically analyzes the retrieved footage and generates detailed descriptions, such as: “At 10:23 AM on March 15, 2024, in the extrusion line on the second floor of Factory A, worker Kim ○○ was found operating machinery without safety gloves. Immediate corrective action was taken by the site supervisor.” These objective and consistent records become powerful legal evidence in the event of disputes.

3. 3D Spatial Auto-Mapping (3D Digital Twin): Intuitive Safety Management and Spatial Optimization

Manufacturing environments are constantly evolving, and safety management systems must keep pace. Superb AI’s 3D spatial auto-mapping technology offers a groundbreaking solution to this challenge. As real-time worker movement data accumulates within the 3D space, in-depth analysis of the work environment becomes possible.

For instance, if inefficient and overlapping movement patterns are detected in a specific area, the system might generate an insight such as: “70% increased risk of worker collision at the intersection of Line B.” Similarly, it can automatically identify patterns like: “Increased frequency of close contact between forklifts and workers in the narrow aisle of Zone C.”

This type of spatial analysis plays a crucial role in meeting the regulatory requirement to proactively identify and mitigate environmental risk factors. It also enables companies to detect newly introduced hazards—such as those resulting from layout changes—early and take preemptive action.

Step-by-Step Guide to Implementing an AI-Powered Video Analytics System in Manufacturing

1. Diagnose and Analyze Risk Factors

- Assess the on-site environment and identify risk factors by task type

- Analyze past incident data to uncover vulnerabilities

- Identify gaps between legal requirements and current safety management practices

2. Build an Integrated Monitoring System Using Multi-Source Video Input

- Strategically deploy and integrate CCTV cameras across the facility

- Enable real-time, centralized monitoring through a centralized control system

3. Activate AI-Based Event Detection and Alert System

- Detect real-time changes and immediate safety threats

- Set up tiered alert levels based on risk severity

- Establish a multi-layered response system including on-site alarms, equipment control, and staff notifications

4. Accumulate Safety Management Data as Evidence

- Automatically store footage of detected safety events and record metadata

- Generate safety incident reports automatically using the VLM technology

- Regularly analyze safety data to detect patterns and trends

5. Provide Customized Reports and Dashboards

- Build dashboards for executives to easily monitor the overall safety status of the site

- Visualize safety performance metrics by department or process

- Automatically generate legally compliant evidence reports for safety requirements

6. Continuously Improve and Optimize the System

- Continuously enhance AI models through integration with the MLOps platform

- Incorporate on-site feedback to fine-tune the system

- Update the system as safety regulations evolve

Conclusion: A Proactive Strategy for Ensuring Facility Safety

The Korean government recently announced a focused inspection plan targeting high-risk industrial sites. In manufacturing—especially sectors like shipbuilding and repair where fatal accidents are on the rise—there is an urgent need for companies to build more systematic and proactive safety management systems.

Superb AI’s Video Analytics solution goes beyond traditional CCTV monitoring to deliver a holistic safety management system. Powered by a state-of-the-art vision foundation model, it enables 24/7 real-time monitoring, rapid incident analysis via natural language search, and agile adaptation to on-site changes through 3D spatial mapping technology.

This solution not only helps companies fulfill their legal obligations to ensure workplace safety and health, but also contributes to achieving their core business goals of improved productivity. Especially for small businesses and high-risk industries where safety capabilities are urgently needed, Superb AI’s solution, which allows for immediate AI deployment without pre-training, offers a highly strategic choice.

While growing regulatory pressure does pose a heavier burden for businesses, it can be turned into an opportunity to overhaul industrial safety culture and build a forward-looking safety management system that ensures worker protection and long-term business sustainability. Superb AI is ready to partner with you on that journey.

Related Posts

Insight

CVPR 2025 Foundation Few-Shot Object Detection Challenge: Transforming Future Industries with AI

Hyun Kim

Co-Founder & CEO | 10 min read

Insight

How Can Vision AI Recognize What It Has Never Seen Before? LVIS and the Future of Object Detection

Hyun Kim

Co-Founder & CEO | 15 min read

Insight

Interactive AI in the Field? Exploring Multi-Prompt Technology

Tyler McKean

Head of Customer Success | 15 min read

About Superb AI

Superb AI is an enterprise-level training data platform that is reinventing the way ML teams manage and deliver training data within organizations. Launched in 2018, the Superb AI Suite provides a unique blend of automation, collaboration and plug-and-play modularity, helping teams drastically reduce the time it takes to prepare high quality training datasets. If you want to experience the transformation, sign up for free today.